DIN 50017 Temperature Test Chamber Environmental Condensate

Product Details:

| Place of Origin: | China |

| Brand Name: | LIB |

| Certification: | CE,ROHS |

| Model Number: | ATH-100A |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Packaging Details: | Wooden Cases Standard Export Package |

| Delivery Time: | 5-14 Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability: | 210Sets/quarter |

|

Detail Information |

|||

| Humidity Range: | 95%RH ~ 100%RH | Temperature Range: | 10℃ ~ +60 ℃ |

|---|---|---|---|

| Sample Shelf: | 1pc Sample Shelf + 1pc Round Bar | Water Trough: | Build-in Water Trough In Testing Room; |

| Controller: | Ethernet Connection, USB Port | Water Supply System: | Automatic Water Supply |

| High Light: | DIN 50017 Temperature Test Chamber,Environmental Condensate Temperature Test Chamber,DIN 50017 environmental temperature test chamber |

||

Product Description

Description

Condensate temperature test chamber is suitable for the electroplating coating test of electronic and electrical products, automotive aviation military equipment, hardware tools and other product parts, metal materials and products.

Technical Specification

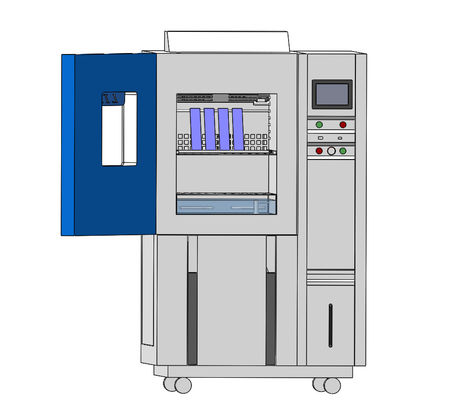

| Name | DIN 50017 Environmental Condensate Temperature Test Chamber |

| Model | ATH-100A |

| Internal Dimension (mm) | 400*500*500 D*W*H |

| Overall Dimension (mm) | 900*1050*1620 D*W*H |

| Temperature Range (℃) | 10℃ ~ +60 ℃ |

| Humidity range | 95%RH ~ 100% |

| Cooling Rate | 1°C / min |

| Heating Rate | 3°C/ min |

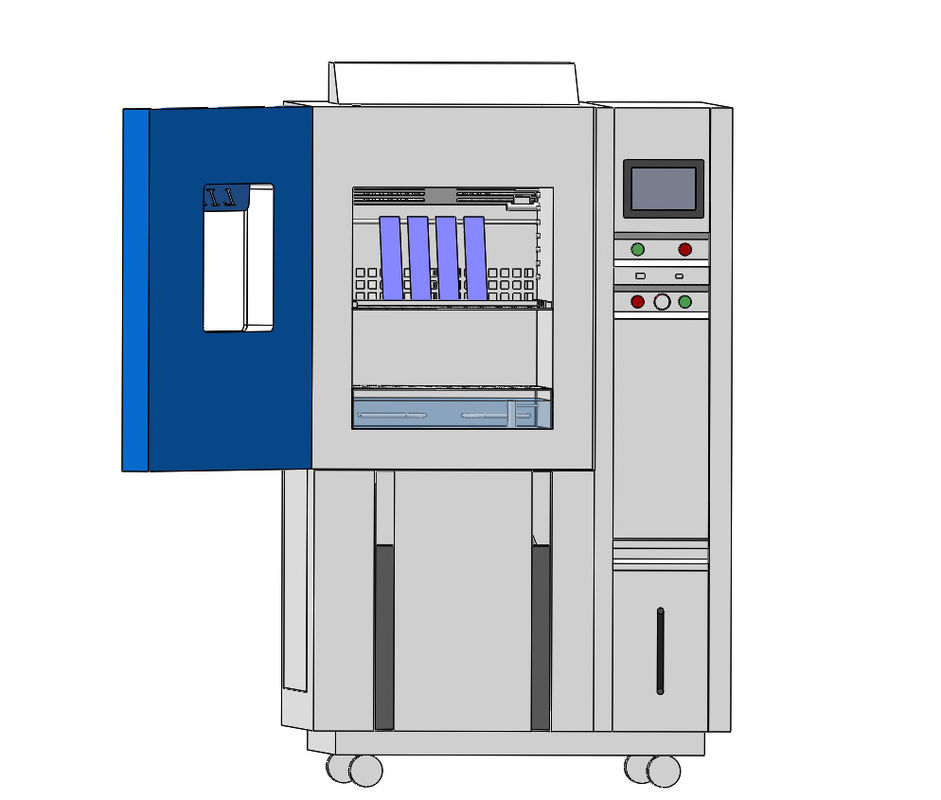

| Testing room roof | Slope shape designed, to avoid condensate drop on samples |

| Sample shelf | 1pc sample shelf + 1pc round bar |

| Water trough | Build-in water trough in testing room |

| Controller |

Programmable color LCD touch screen controller |

| Temperature Sensor | PTR Platinum Resistance PT100Ω/MV A-class |

| Humidity sensor | Dry and wet bulb sensor |

| Air circulation | Centrifugal wind fan |

| Water supply system | Automatic water supply; Water purification system |

| Exterior material | Steel Plate with protective coating |

| Standard configuration | Dia50mm port on left side, with plug |

Details

| |

|

|

Temperature and Humidity Sensor ●PT-100 Class A sensor, real-time accurate detection and display of temperature changes at 0.001 degrees. ●A wet gauze and a real-time temperature, converted by temperature difference, showing real-time relative humidity.

|

Condensation Constitute ●CondensationClimatic Chamber ●Condensation can be formed on the surface of the test specimens by cooling the chamber air temperature and testing specimens ●The condensate is composed by condensation water and dissolved matter from test specimens during testing |

DIN EN ISO 6270-2 Test Procedure

Environmental condensation chamber

1. Put the test piece

2. Close the test chamber door

3. Turn on the heating device used to heat the water of the trough or the box to heat the working room to the air temperature required in the first stage

It must be reached within 1.5 hours, and condensate must be formed on the test piece

Condensate Alternating Temperature and Humidity Test AHT

Condensate temperature test chamber

1.There are two stages, the first stage terminates the condensation process after 8 hours of heating

2.The second stage, 16 hours of cooling: open the equipment door and perform ventilation

3.Check the amount of water in the trough during the test 16 hours, and add water if necessary, then close the door and turn on the heating device to start a new cycle.

Condensate alternating temperature test AT

Condensate alternating test chamber

1.There are two stages, the first stage terminates the condensation process after 8 2.hours of heating

3.In the second stage, check the amount of water in the trough after 16 hours, and add water when necessary, and then turn on the heating device again to start a new cycle